Enhancing Your Business with Rapid Prototype Service

In the competitive landscape of metal fabrication, businesses are constantly looking for ways to innovate, improve efficiency, and reduce time-to-market. One of the most effective methods to achieve these goals is by utilizing a highly efficient rapid prototype service. In this comprehensive article, we will explore how a rapid prototype service can revolutionize your operations, enhance product quality, and ultimately drive business success.

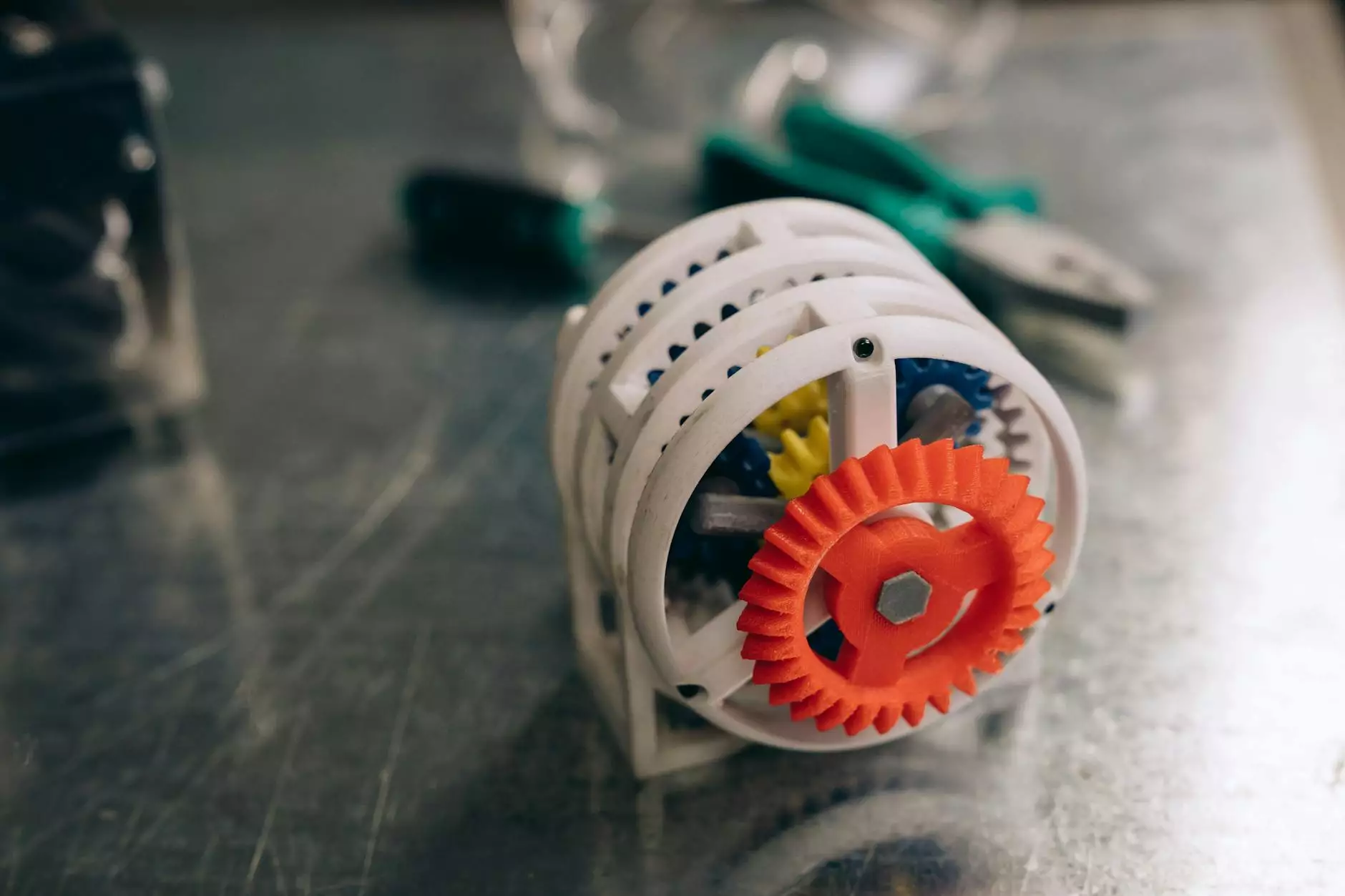

Understanding Rapid Prototyping

Rapid prototyping encompasses a range of techniques utilized to quickly fabricate a scale model or functional part of a physical component. This process uses various methods such as:

- 3D Printing: The most renowned technique, which allows for layer-by-layer material application using digital models.

- CNC Machining: Subtractive manufacturing that carves out parts from a solid block of material.

- Vacuum Casting: A method ideal for producing small quantities of silicone rubber molds and casting products.

The essence of rapid prototyping lies in its ability to accelerate the design cycle, allowing for quicker feedback and iterations, which is crucial for successful product development in the metal fabrication sector.

The Benefits of Rapid Prototype Service in Metal Fabrication

In the metal fabrication industry, the adoption of a rapid prototype service presents numerous advantages:

- Accelerated Product Development: Rapid prototyping enables designers to create models swiftly, resulting in reduced lead times.

- Cost Efficiency: Early-stage prototypes help identify flaws before mass production, slicing down on costly changes.

- Enhanced Creativity: Designers can experiment with various designs and materials without the long-term commitment of full production.

- Improved Collaboration: Physical prototypes can facilitate better communication among teams and clients by providing tangible assets to discuss.

- Real-Time Testing: Prototypes allow for immediate testing of functionality, performance, and aesthetics.

How Rapid Prototyping Fits into Modern Business Strategies

Incorporating rapid prototype service into your business strategy aligns perfectly with modern operational methodologies such as Lean Manufacturing and Agile Development. Here’s how:

Integration with Lean Manufacturing

Lean Manufacturing emphasizes waste reduction while ensuring high-quality production. Rapid prototyping allows businesses to eliminate waste by:

- Identifying design flaws early in the process.

- Reducing the number of iterations required to finalize a design.

- Enabling quicker responses to market changes.

Support for Agile Development

Agile Development revolves around flexibility and customer feedback. Rapid prototyping supports Agile by:

- Allowing developers to create functional prototypes for user testing.

- Facilitating quick adjustments based on real user input.

- Encouraging iterative development and continuous improvement.

Choosing the Right Rapid Prototype Service Provider

Selecting the right rapid prototype service provider is crucial for maximizing benefits. Here are key factors to consider:

Experience and Expertise

Look for a service provider with a proven track record in your industry. Providers who understand the nuances of metal fabrication will offer insights that can significantly contribute to the quality of your prototypes.

Technology and Equipment

The latest technology yields the best results. Verify the equipment and techniques the provider utilizes:

- Does it include advanced 3D printers and CNC machines?

- Are they using up-to-date technologies that enhance precision and finish?

Material Options

Material flexibility is vital. Ensure your provider offers a wide range of materials suitable for your prototyping needs, including metals, plastics, and composites.

Turnaround Time

Fast turnaround is a central tenet of rapid prototyping. Choose a provider known for their efficiency without compromising quality.

The Process of Rapid Prototyping

Understanding the basic steps involved in the rapid prototype service process can help you communicate better with your provider:

- Concept Development: Generate ideas and design initial concepts.

- 3D Modeling: Create a detailed, digital 3D model of the design.

- Prototype Fabrication: Use the selected manufacturing method to produce the prototype.

- Testing and Evaluation: Assess functionality, durability, and performance.

- Revisions: Make necessary adjustments and repeat testing.

Case Studies: Successful Implementation of Rapid Prototyping

Examining real-world applications of rapid prototyping in metal fabrication can provide valuable insights into its transformative power. Here are notable case studies:

Case Study 1: Automotive Parts Manufacturer

An automotive parts manufacturer integrated rapid prototyping into its workflow. By developing prototypes for new engine components early, they drastically reduced design flaws and cut production time by 30%, leading to faster product launches and substantial cost savings.

Case Study 2: Aerospace Component Fabricator

In the aerospace sector, a component fabricator began utilizing rapid prototyping for testing wing structures. This allowed them to simulate real-world stresses on a model, leading to innovative designs that increased fuel efficiency by 10% in final products.

Future Trends in Rapid Prototyping

The field of rapid prototyping is evolving, and staying ahead of the trends can maximize your business benefits:

- Artificial Intelligence (AI): AI algorithms are increasingly being used for optimizing designs and simulations.

- Advanced Materials: The development of new materials, including biomaterials and composites, will expand the capabilities of rapid prototyping.

- Integration with IoT: Smart prototypes connected to the Internet of Things (IoT) can allow for real-time data collection and analysis.

Conclusion

The implementation of a rapid prototype service can significantly elevate your metal fabrication business. By reducing time and costs while improving product quality, your business can emerge as a leader in the industry. Whether you are enhancing your existing processes or embarking on a new project, rapid prototyping serves as a cornerstone of innovation. Explore these options and seize the opportunity to reshape your business using cutting-edge technologies available at Deep Mould today.